Description

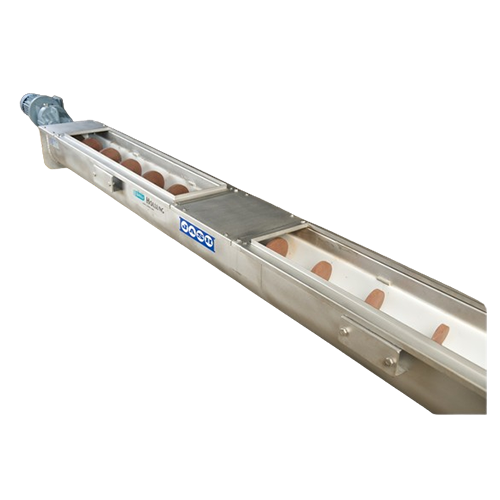

Shaftless Screw Conveyors, Model STC

Jash Shaftless spiral conveyors, Model SSC are a type of material handling equipment used to move bulk materials horizontally or at an inclination. Unlike traditional screw conveyors, shaftless spiral conveyors do not have a central shaft running through the middle of the spiral, which offers several advantages. These conveyors usually find their application for conveying most of the hygroscopic and difficult materials with high discharge rates. The design is well-suited for handling materials in environmentally sensitive applications, such as handling sludge or other materials in wastewater treatment plants.Here are some key features and benefits of shaftless spiral conveyors:

Technical Specifications:

Description | Specifications |

Material Construction | Stainless Steel: The use of stainless steel in the construction of the trough and screw ensures corrosion resistance and hygiene, making these conveyors suitable for industries where cleanliness and sanitation are crucial, such as in food processing. |

Screw Design | Helical Auger: The conveyor screw, also known as the auger, is a helical screw that rotates within the trough. The design and pitch of the screw flight affect the conveyor’s capacity, efficiency, and the type of material it can handle. |

Versatility | Materials Handling: Stainless steel trough screw conveyors can handle a wide range of materials, including powders, granules, flakes, and other bulk materials. Customization:Conveyors can be customized to suit specific applications, taking into consideration factors such as material type, flow rates, and space constraints. |

Sanitary Design | Easy Cleaning: The smooth surfaces of stainless steel make it easy to clean, which is crucial in applications where sanitation is a priority, such as in the food and pharmaceutical industries. Sealed Construction: Troughs can be designed with seals and gaskets to prevent material leakage and maintain a clean environment. |

Drive Options | Motor Types: Screw conveyors can be powered by various types of electric motor configurations. The choice of motor depends on factors such as the required capacity, speed, and the nature of the materials being conveyed. |

Inlet and Outlet Options | The conveyors can be designed with different inlet and outlet configurations to accommodate specific material loading and discharge requirements. |

Maintenance and Safety | Access Points: Consider designs that facilitate easy access for maintenance and cleaning. Safety Features: Incorporate safety features such as guards and emergency stop to ensure safe operation. |

Capacity and Power Requirements | Capacity: The conveyor’s capacity is influenced by factors like the screw diameter, pitch, and rotational speed. Power Requirements: The power needed to drive the conveyor depends on factors such as the material’s characteristics and the conveyor’s design parameters. |

Optional Features on request | Special material of construction Provision for clean in place (CIP) |

Applications | Food Processing, Plastics, Chemicals, Petrochemicals, Pharmaceuticals, Distilleries, Breweries, Dosing and mixing, Paint and resins, Fertilizers, Sugar processing, Baby food processing, Solid waste management, etc. |

Reviews

There are no reviews yet.