Description

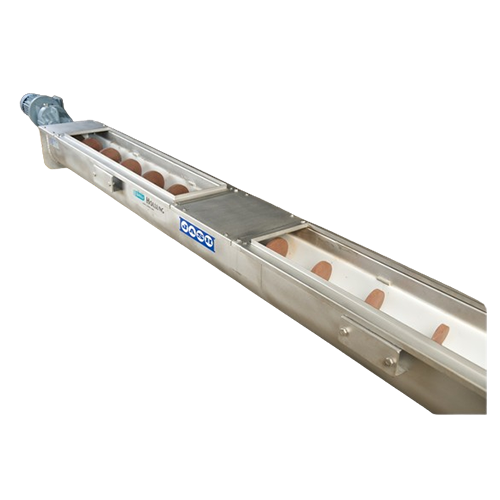

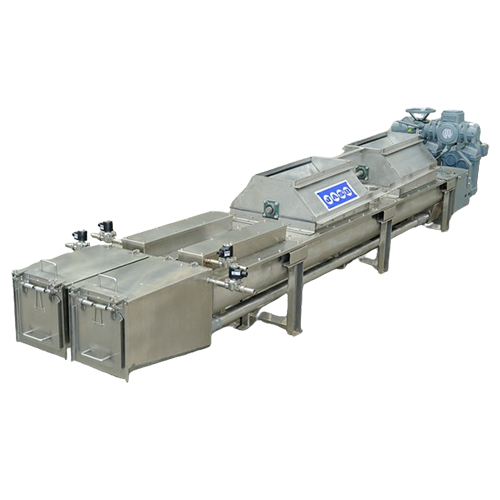

Trough Screw Conveyors, Model TC

Our Mild steel trough screw conveyors, Model TC are similar to stainless steel trough screw conveyors in terms of their basic design and function, but they differ in the material used for construction. Mild steel, also known as carbon steel, is a common choice for troughs and screws in screw conveyors, especially when the application doesn’t require the corrosion resistance offered by stainless steel or process which doesn’t require a hygienic manufacturing setup.

Technical Specifications:

Description | Specifications |

Material Construction | Mild Steel (Carbon Steel): Mild steel is a cost-effective material that is often used in screw conveyor construction when corrosion resistance is not a primary concern. It’s suitable for various industrial applications. |

Screw Design | Helical Auger:Similar to stainless steel screw conveyors, mild steel trough screw conveyors feature a helical screw that rotates within the trough. The screw design affects the conveyor’s performance and efficiency. |

Versatility | Materials Handling:Mild steel screw conveyors can handle a wide range of materials, such as powders, granules, and bulk solids. Customization:Like stainless steel conveyors, mild steel conveyors can be customized based on the specific requirements of the application. |

Cost Effective Solutions | Mild steel is generally less expensive than stainless steel, making mild steel trough screw conveyors a cost-effective solution for applications where corrosion resistance is not critical. |

Drive Options | Motor Types: Screw conveyors can be powered by various types of electric motor configurations. The choice of motor depends on factors such as the required capacity, speed, and the nature of the materials being conveyed. |

Inlet and Outlet Options | The conveyors can be designed with different inlet and outlet configurations to accommodate specific material loading and discharge requirements. |

Maintenance and Safety | Access Points: Consider designs that facilitate easy access for maintenance and cleaning. Safety Features: Incorporate safety features such as guards and emergency stop to ensure safe operation. |

Capacity and Power Requirements | Capacity: The conveyor’s capacity is influenced by factors like the screw diameter, pitch, and rotational speed. Power Requirements: The power needed to drive the conveyor depends on factors such as the material’s characteristics and the conveyor’s design parameters. |

Coatings and Surface Treatments | While mild steel is more susceptible to corrosion compared to stainless steel, coatings and surface treatments (such as paint or galvanization) can be applied to provide some level of corrosion protection. |

Optional Features on request | Special material of construction Trough Liners (Stainless steel/Hardox/UHMWP) Hard facing on the screw flight Hanger bearings |

Applications | Coal handling, Fly Ash handling, Cement, Steel, Chemicals, Petrochemicals, Animal feed, Mining, Mineral processing, Foundries, Grain handling, Solid waste management, etc. |

Reviews

There are no reviews yet.